![]()

|

James Sadler & Sons Ltd |

Location and period of operation:

|

Sadler & Co |

Burslem |

1882 |

1889 |

|

James Sadler & Sons |

Burslem |

1899 |

March 2000 |

Earthenware manufacturer at

the Wellington and Central

Potteries, Burslem,

Stoke-on-Trent, England

|

jump to:

| James Sadler adverts | Typical ware produced by James Sadler |

| example of transfer decorating | marks used on ware |

1999 re-branding 2000 take over by Churchill

Sadler's Wellington and Central

Potteries

- click for more -

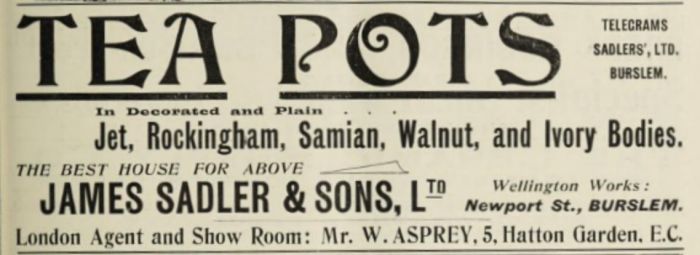

James Sadler adverts

Teapots in Decorated and Plain..

Jet, Rockingham, Samian, Walnut, and Ivory Bodies.

the best house for above

JAMES SADLER & SONS, Ltd

Wellington Works: Newport St., Burslem

Advert - Pottery Gazette, February 1906

|

James Sadler & Sons, Ltd., Wellington Works, Newport street, Burslem, are manufacturers of teapots, they have a wide reputation for the variety and quality of their productions. The question of convenient utility has practically settled the form of the domestic teapot. The relative positions, and even the shapes of the handles and spouts, are almost uniform in all grades, from the most artistically decorated china ware down to the cheapest stoneware. Still, manufacturers who make teapots their specialty, as Messrs. Sadler & Sons do are able to impart variety in the form of the body of the pot. That the company do this successfully may be seen from an inspection of their samples, which are on show at the rooms of their London representative, Mr. W. Asprey, 5 Hatton-garden E.C. They make a varied assortment of shapes in teapots in jet, Rockingham, Samian, Walnut, mottled, and Ivory bodies. One of their new shapes - the "Wellington" — is supplied in all these bodies, and in several sizes The "Regent" shape in Samian decorated and gilt, is a handsome pot. The Rockingham pots, in a number of shapes specially suitable to that ware, are good selling lines, as also are the black Rockingham pots. The company claim a specially hard body for these goods Teapots in ivory bodies, floral decorations and gilt, are good lines of a better class. The samples now on show fully maintain the reputation of the company for medium and cheap teapots of good quality. The Pottery Gazette, 1st January 1907 |

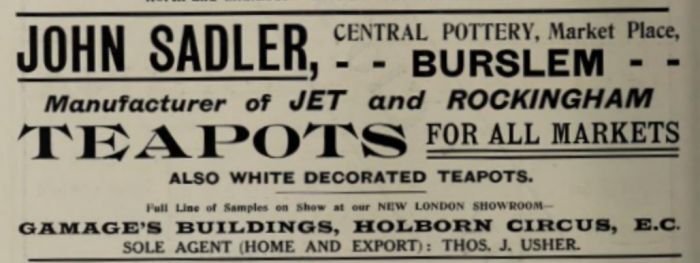

JOHN SADLER

Central Pottery, Market Place, Burslem

Manufacturer of Jet and Rockingham Teapots for all Markets

also white decorated teapots

Advert - Pottery

Gazette, September 1908

|

John Sadler (one of the sons) had a separate business producing teapots at the Central Pottery, Market Place, Burslem. In 1920 the two family businesses were merged together at the Central Pottery which was renamed to the Wellington & Central Potteries. |

|

Pottery Gazette and Glass Trade Review - August 1945 |

Sadlers' teapots for all markets Pottery

Gazette Reference Book - 1947 - click for more - |

during

and just after the Second World War only utilitarian ware was

allowed to be produced, under

the Wartime

Concentration Scheme.

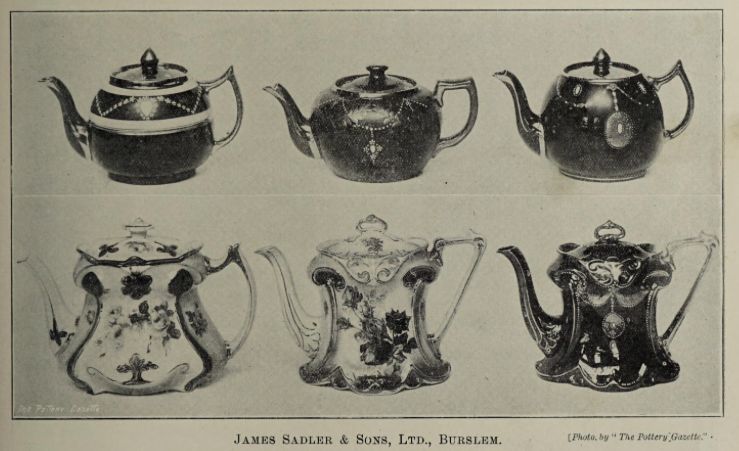

Typical ware produced by James Sadler & Sons Ltd:

|

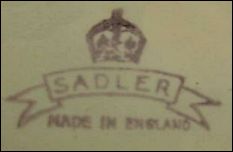

"Sadler was primarily a specialist manufacturer of plan and fancy teapots, but the company also produced art pottery, kitchenware (under the 'Kleen' brand), vases, giftware and novelties. It also manufactured for the catering and hotel trade. Marks include the name or initials, and from c.1947 the same 'Sadler' on a banner below a crown." A handbook of British Pottery Manufacturers - Michael Perry An advert from 1939 states "In addition to the novelty teapots we specialize in... Samian & Mottled Teapots, Cafe & Hotel Ware, Coloured Glaze and Fancy Decorated Teapots" By 1999 they had 750 product lines. |

James Sadler & Sons,

Ltd., Burslem

Pottery Gazette, April 1910

In 1909 Sadler introduced their "Latest specialty - the B.A. Tea Pots (patented) The B.A. TEAPOT comprises the best and simplest arrangement for brewing perfect tea ; no screws to adjust, no rubber or metal to spoil the flavour of the tea, and all the tea leaves are retained in the teapot." They also had a patented Lock-Lid Teapot which allowed the teapot to be poured past the vertical without the lid falling off. |

this style is the 'Louis'

shape but is generally

known as the Cube-Shape - it was introduced around 1956

Sadler produced teapots in 100s and 100s of designs and patterns

|

|

|

|

teapots

were by far the overwhelming share of the output of the Sadler factory,

however they did produce accompanying storage jars, novelty ware and their 1950s

KLEEN kitchen ware range

|

|

|

|

designs

of the 1960s and 70s

the teapot on the left has the mark

shown, the teapot on the right just has the cast-in SADLER ENGLAND

example of transfer decorating

|

|

|

|

Sadler Championships mark with a trophy cup |

Sadler Championships |

Wellington Championships mark with a trophy cup |

Windsor |

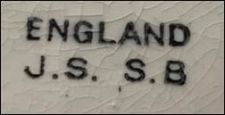

Initials and marks used on ware for identification:

|

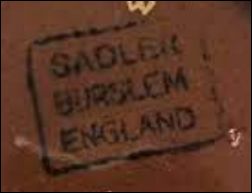

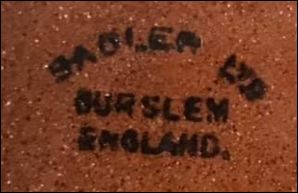

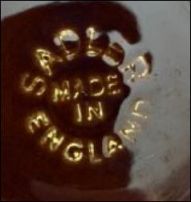

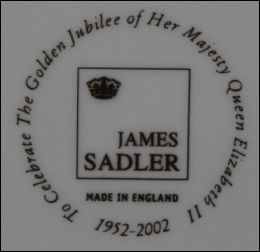

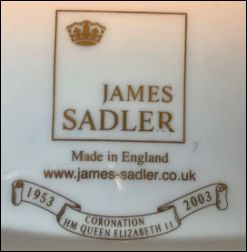

Godden (Encyclopaedia of British Pottery and Porcelain Marks) only records three marks for James Sadler: ENGLAND 1899 - c. 1937

SADLER 1937+

c. 1937+

There were variations on these marks, especially for special and commemorative editions - these are self evident. Many items have the Sadler name cast-in, this cut down on costs as the marking was produced when the ware was cast. |

ENGLAND

J. S. S. B.

Godden records this printed or impressed mark as 1899-c. 1937

the initials JSSB stand for James Sadler & Sons, Burslem

SADLER BURSLEM ENGLAND |

SADLER Ltd BURSLEM ENGLAND |

1937 +

SADLER MADE IN ENGLAND |

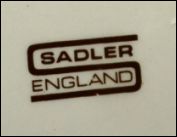

SADLER ENGLAND |

includes the printed mark c.1947+ |

many items have the Sadler

name cast-in, with and without other printed marks

SADLER

Made in England

c. 1947+

|

this mark after the take-over by Churchill China in 2000 as Sadler were an earthenware manufacturer |

2000+ "In order to try to remain competitive, |

'Wellington' is the name of the Sadler factory and was used as a trade name in some marks

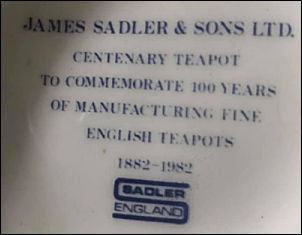

James Sadler & Sons Ltd Centenary Teapot to commemorate 100 years of manufacturing fine English teapots 1882-1982 |

SADLER ENGLAND

|

1982 +

|

|

|

|

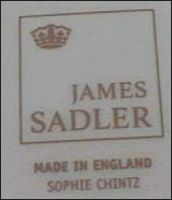

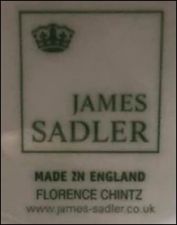

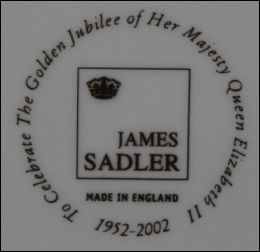

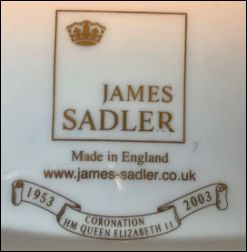

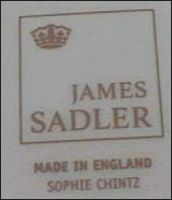

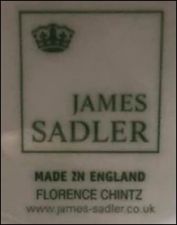

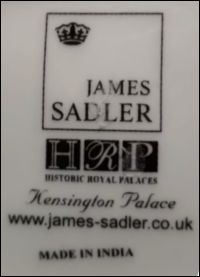

style of mark introduced in 1999

as part of the Sadler's re-branding exercise

|

|

commemorative ware produced by Churchill with the James Sadler brand name

c. 2000-21

|

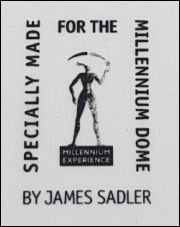

Sadler - 1999 re-branding: Falling sales and increasing costs resulted in a major restructure launched in 1999 - as well as redesigning and re-branding, product lines were reduced from 850 to 340. A new corporate logo, brand identity and internet presence was launched. Sadler made a range of ware for sale at the 2000 Millennium Dome Experience at Greenwich, London. The workforce had dwindled over the years from 500 to 140 and under the restructure was trimmed by half to 70 and "In order to try to remain competitive, some production [was] outsourced overseas". |

|

|

|

|

style of mark introduced in 1999

as part of the Sadler's re-branding exercise

James Sadler

Historic Royal Palaces

Kensington Palace

Made in India

"In order to try to remain competitive,

some production had been

outsourced overseas"

Sadler made a range of ware for sale at the 2000 Millennium Dome Experience at Greenwich, London

|

Specially made for the Millennium Dome by James Sadler |

|

From the 1999 Sadler's

web site, as part of the brand re-launch:

James Sadler was founded in 1882, and is one of the leading manufacturers of teapots in the UK. It all began with James Sadler, who built a factory in Burslem at the heart of the ceramic industry in Stoke-on-Trent, and made a name for himself by making fine earthenware teapots. He soon became famous, and a James Sadler teapot became synonymous with quality and good taste. The first teapots were made using a red clay with a dark brown glazed surface. The Rockingham Brown, or 'Brown Betty' as it is affectionately known, is still in production today using a more elegant, less utilitarian, white clay. From these beginnings, the company has flourished and grown to the size it is today. It is an encouraging thought that the original James Sadler, whose great-grandson is the current chairman, would have approved of the diversity and design of the range today. His vision and commitment to understanding what the customer really wanted is the foundation on which the company was built, and is our philosophy today. The rapid growth of the ceramic industry in the nineteenth century brought prosperity to Staffordshire, and the world passion for English pottery in the middle of this century, meant that James Sadler products very quickly became world famous. You can find our ranges on sale in over 100 countries around the world, from the USA to Australia, and from Russia to Brazil! We are proud of our history and our commitment to the future. Remember, if it doesn't have the James Sadler mark, it isn't a James Sadler teapot! |

| Sentinel Newspaper article,

17th February 1999,

Andy Stanistreet Big makeover for next millennium

For the first time in 117 years, the family-owned firm of James Sadler has been given a new corporate logo and brand identity. It has also slashed its product total, introduced new ranges over and

above its traditional ceramic teapot production and re-targeted its

customer base. Up until last October, James Sadler produced around 850 different designs, mostly teapots. Under its new tighter regime, it now produces a total of 340 items, including plates, cups and saucers. 160 of the items are either new designs or refreshed older ones which use contemporary colours or new surface treatments. Design and marketing director Richard Eagleton said:

The new James Sadler brand is also being highlighted to consumers through a dedicated marketing campaign. The company's traditional crown has been updated and kept, but it is now placed on a square copper background with contemporary lettering in white. Mr Eagleton added:

The family name of the firm is also expected to add its weight in marketing the new ranges. Store events, product signings and collectors' evenings are set to be hosted throughout the world by current managing director Mr. Neil Sadler, the great-grandson of the founder of the business. The new brand and products were launched at the Spring Fair in Birmingham last week and are currently on display at the Frankfurt Trade Fair. James Sadler currently exports around half its wares abroad, with its key markets being North America and Europe. PICTURED: Sadler's design and marketing director Richard Eagleton with some of the new ware. |

| Sentinel Newspaper article,

16th March 1999 Ambassador for China Business profile: Neil Sadler by Andy Stanistreet One of the pottery industry's leading

lights has taken on a new role

Neil was born into the ceramics industry. His father Eddie ran Burslem-based teapot manufacturers James Sadler and Son with his uncle, John Sadler. As soon as he was able to walk he was taken on tours of the factory on Saturday mornings, was introduced to high-powered sales representatives and directors from both the UK and abroad and was ‘adopted' by workers only too keen to let him try his budding skills at painting pots and making clay models. But his early introduction into the world of trade and commerce did not end when the factory closed its doors. He occupied a privileged place at the family dinner table. Because of the difficulty of long distance travel in the late 1940s and early 1950s, buyers from North America and Australia frequently stayed in the UK for weeks on end. They were invited to the family home in Acton near Newcastle for evening meals and business discussions as a matter of course.

Aged eight Neil was sent to Mostyn House prep school on the Wirral. Aged 12 he was sent to Stowe public school in Buckinghamshire, where he continued his passion for games and took a particular interest in geography and languages. In his spare time he watched motor races at nearby Silverstone, often begging paddock tickets to watch Stirling Moss and Mike Hawthorn speed round the circuit. It was also at Stowe that he finally accepted he would one day become a

prime mover in the future of James Sadler.

He left Stowe aged 18 and immediately started a course at Stoke Technical College for a diploma in ceramic technology.

After college he returned to James Sadler and became a management trainee, learning the ropes anew.

Every year since then Neil, who was soon afterwards made sales director,

has travelled abroad.

But earlier this year it was decided his role with the company would change. James Sadler, suffering from the effects of the strong pound, ageing products and a lack of public knowledge about its ranges, decided to launch itself big style into the millennium. It scrapped hundreds of products, developed or revamped 160 new designs, altered its branding and launched a full-scale attack to get high profile consumer awareness of its collectability, tradition and quality on top of its already strong trade following. And Neil Sadler — the fourth generation of the founder of the firm — is to become the ambassador of the company, spearheading the initiative throughout the world. Although he's already travelled hundreds of thousands of miles around the globe, very few of his sales trips have been to actually meet the buying public. Now he will be responsible for organising a packed diary of engagements including store events and signings, TV and radio interviews, and jetting across to the far East and Australia to meet collectors and new customers. It is a challenge he relishes.

|

| Sentinel Newspaper article,

17th September 1999, Michael Howard Millennium tonic for pottery companies Millennium ware is helping provide pottery companies with a welcome boost in orders as collectors rush to mark the event. Limited-edition designs and complete ranges are being sold quicker than

expected and teapot producer James Sadler has followed Wedgwood in

announcing a place in London's Millennium Dome. The pot was produced together with design guru Robin Levien and uses a nylon filter to hold the leaves which can then be lifted out to stop the drink stewing. It will be in use in Typhoo's cafe in the dome and on sale in the dome shop, but a much larger number of orders is likely to come when it goes on sale in all 130 branches of Whittard's tea and coffee shops as a millennium teapot. Managing director Richard Eagleton said:

|

|

Ty·phoo t·fresh Teapot "James Sadler, British manufacturer of contemporary homewares, in partnership with Typhoo has created the teapot for the 3rd Millennium. The t·fresh teapot is designed by Robin Levien, Royal Designer for Industry. Using the Chatsford® filter, which has been chosen as the ultimate tea brewing system, with its unique mesh infuser allowing the tea to circulate freely and its ability to be removed to prevent stewing." |

|

Sadler - 2000 collapse and take over by Churchill: The 1999 re-branding was not sufficient to turn the things around and the company experienced a difficult trading period during which the they lost significant sales from Eastern Europe.

|

| Sentinel Newspaper article,

2nd March 2000,

Business Editor Michael Litchfield Trouble brews for Sadler’s teapots The head of the world's most famous

teapot pottery firm, based in Burslem for more than 100 years, was today

refusing to deny rumours that his family-run empire was on the brink of

receivership.

If Sadler does go into receivership, it will be the second great family-run Stoke-on-Trent pottery company to crash within a fortnight, following quickly on the heels of Longton-based John Tams Group. Sadler has been suffering from the strong pound, ageing products and a lack of public knowledge about its ranges. In a desperate fight for survival, it scrapped hundreds of products, developed or revamped 160 new designs, altered its branding and launched a full-scale counter-offensive to try to achieve high-profile consumer awareness. Neil Sadler, aged 56, was last year made a globetrotting ambassador, with the brief to put the company firmly back on the world industrial map. The fourth generation family member arranged store events, TV and radio interviews. In between, he jetted around the world, meeting collectors and potential new customers.

Two weeks ago former chairman Edward Sadler died at the age of 89. That same day he had dictated letters at the factory. In recent years, Sadler has exported ware to dozens of countries, with an overall turnover of more than £4 million. Peter Sadler, aged 58, who had been running the company with brother Neil, said the firm had been forced to change direction ‘‘dramatically'' since their father's era at the helm In order to try to remain competitive, some production had been outsourced overseas. The workforce had dwindled over the years from 500 to 140. In recent times, the company had been producing 10,000 teapots a week in Burslem. Mr Sadler's son, Matthew, aged 25, who has been in charge of imports, was hoping to become chairman one day and keep the family tradition alive. By early this week the industry was awash with rumours of Sadler going into receivership. Two Sadler suppliers called The Sentinel to say they had "blacklisted'' the company because "the word in the industry'' was that Sadler's would be in receivership by Thursday. |

| Sentinel Newspaper article,

6th March 2000,

Business Editor Michael Litchfield Jobs threat as pottery goes into receivership A total of 140 workers at specialist teapot manufacturer James Sadler and Sons Ltd face an uncertain future after it went into administrative receivership today. Joseph Atkinson, corporate recovery partner of Deloitte and Touche in Birmingham, said:

The company's freehold factory is based in the centre of Burslem. Founded in 1882, it has been exporting to all parts of the world. Only last Thursday, The Sentinel reported that Sadler's was on the brink of becoming the second great family-run Stoke-on-Trent pottery company to crash into receivership within a fortnight, following hot on the heels of Longton-based John Tams Group. The receivers' statement continued today:

Helping Mr Atkinson with the administration will be his partner Andrew Peters. They will be working closely with the current Sadler management team to keep the company trading. No jobs are likely to be lost until the whole financial position has been reviewed. The company has been suffering from a strong pound, ageing products and a lack of public knowledge about its ranges. In a desperate fight for survival, it scrapped hundreds of products, developed or revamped 160 new designs, and altered its branding. The company's annual turnover in recent years has been in excess of £4 million. Peter Sadler, aged 58, who has been running the company with brother Neil, said the firm had been forced to change direction ‘‘dramatically'' since their father's era at the helm. In order to try to remain competitive, some production had been outsourced overseas. |

| Sentinel Newspaper article,

5th April 2000,

Business Reporter Stephen Houghton Churchill's show of confidence by buying Sadler

Churchill announced today it has purchased the right to use the historic teapot company's brand-name, designs and archives, along with some product lines and stock. The move, which comes after James Sadler and Sons controversially went into receivership, is expected to lead to Churchill employing up to 15 of the firm's 70 remaining staff. Industry experts today pointed to the purchase as a sign of confidence by Churchill after rival Steelite International bought a 7.1 per cent stake in the company. Churchill Dining-In sales and marketing director Simon Bell believes the move could lead to a massive boost in turnover and help secure the future of its 1,300 workers. He said:

Mr Bell confirmed the company was keen to compete in the collectors' market, which made Sadler's archives particularly valuable. He also stressed Churchill intends to operate the James Sadler brand as a separate entity, although its activities will be 'absorbed' at the group's Alexander site in Cobridge. The factory, one of four owned by Churchill in the Potteries, has a

purpose-built casting facility.

Mr Roper pointed out the company had made

"one or two'" purchases

in the past, including its Marlborough works from the receiver of Alfred

Meakin in 1979. This week's sale, for an undisclosed sum, does not include the James Sadler and Sons building in Burslem. However, telephone calls to the factory were today being fielded by a

representative from Churchill China. Mr Bell explained this was to make the current situation clear to

callers. James Sadler and Sons, which has been trading since 1882, has been run by administrative receivers Deloitte and Touche for the past month. Chairman Peter Sadler sparked a storm of controversy by blaming his firm's failure on cheap foreign imports, while at the same time running a business importing products from the Far East. Mr Sadler, who is chairman of James Sadler Imports Limited and recently admitted plans to set up an import facility in Newcastle, was today unavailable for comment. Deloitte and Touche confirmed James Sadler and Sons' Burslem-based workforce has already been trimmed by half to 70, meaning Churchill's move will leave a further 55 facing the dole. Corporate recovery partner Joseph Atkinson confirmed his firm would

ensure existing orders were met, but said: "The workforce has been

reduced from 140 to 70 and further redundancies are likely.''

The Sentinel reported this week that Steelite International had bought a

7.1 per cent stake in Churchill China, which is worth around £12.5million. Richard Platt, of Hanley-based stockbroker Pope and Sons, today claimed the purchase of James Sadler and Sons' name was unlikely to effect the situation. Mr Platt explained a takeover did not appear imminent, and that companies were not valued purely on their assets but on their profitability. He said:

Kevin Farrell, chief executive of the British Ceramics Confederation, agreed Churchill's purchase of the brand-name was a sign of confidence. He said:

PICTURED: Churchill's Alexander Pottery, Cobridge, where the Sadler products will be made |

|

|

commemorative ware produced by Churchill with the James Sadler brand name

Questions, comments, contributions? email: Steve Birks