|

Tunstall was a centre

for brick and tile manufacture, and in 1858 it was claimed that at The

Tileries there, owned by Thomas Peake, bricks and tiles had been produced

for nearly two centuries.

By 1817 Tunstall was noted

for its manufacturer of 'a superior kind of blue tile'. Staffordshire blue

bricks were also made and used in paving the side-walks of the newly laid

out streets.

By the late 1820's Thomas

Peak in Watergate Street and Robert Shufflebotham at Clayhills were making

bricks and tiles.

By 1834 there were 5 manufacturers in the area.

Peake's works were the largest and used steam-driven engines for crushing

and preparing the clay.

Thomas Peake's son John

Nash Peake (b.1837 d.1905) succeeded his father in 1861 - by the time of

his death in 1905 he had doubled the size of the works and with 35 ovens

and kilns were one of the largest manufacturers in the country.

John Nash Peake was a

noted public figure and, for many years, was the leader of the Liberal

Party in North Staffordshire.

There is a street in the clayhills area of Tunstall named 'Nash Peake

Street'

photo courtesy of

'Tarboat -Flickr'

J N Peake

photo: Ken

Perkins

These

bricks were reclaimed during the demolition in 2008 of Bennett Street in

Middleport area of Burslem. These houses dated back to 1875.

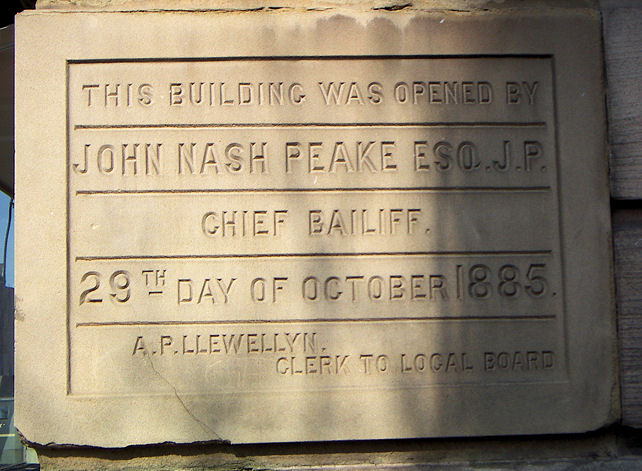

Tunstall Town Hall

Date stone - opening of

tunstall Town Hall in 1885 by John Nash Peake

In 1858 it had an estimated annual output

of 1.5 million paving bricks and 700,000 ordinary bricks.

In 1841 an ovenman employed at The

Tileries gave an account of the organisation of the works to a

representative of a Commission looking into child employment:-

The works was made up

of 8 brickyards and employed between 85 and 100 men with an unspecified

number of young children. The key figure was the ovenman himself, who

had under him, and paid, gangs of boys and girls. He also paid the

moulder, who in turn employed one man (the temperer) and one or two boys

to hand him the clay and to carry the unfired bricks to the flats to

dry. Some boys were required to stay up all night at the ovens to stoke

the fires, their only shelter being a small shed containing bedding

straw. Oven work and clay work were done outdoors, only moulding carried

on under cover. In claiming that the work was healthy, the ovenman

asserted that he preferred it 'a good deal to being pent up in the

pot-works'

A 1951

directory records over 30 brick and tilemakers in the Potteries, but these

were probably of no great size apart from Peakes Tileries.

|