Local History- Unit 1: Settlement & History, Steve Birks

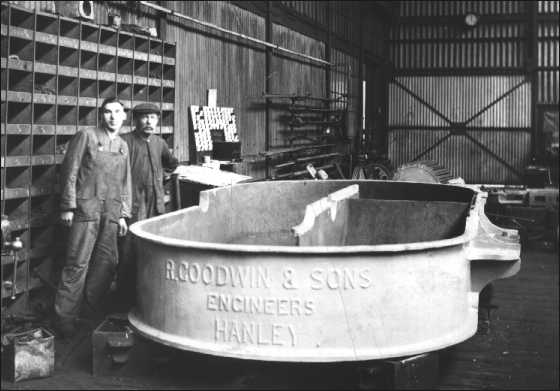

Goodwin foundry was started in 1883 on Ivy House Road, Hanley, Stoke-on-Trent, alongside the Caldon canal, on the opposite side of the canal was the Eagle works of J & G Meakin built in 1859.

R. Goodwin and Sons (Engineers) Ltd were an Iron foundry and engineers supplying castings and equipment to local industry.

The following are extracts from first years books:

Materials paid for

| Engine

& lathe Boiler Drilling Machine 1 pair of bellows 1 bell & safety valve Lathe, rack & 3 pulleys Paid to Smith for old metal Stocks & Dies gas threads 1 Ratchet Brace & 4 taps gas Pattern Makers tools 1 spirit level 2 oil cans 1 strap punch 2 Brushes 6 Strap laces Repairing belts For coke 1ton 1cwt 0qtr @ 27/6 per ton From Granvilles 1 Steam Gauge To timber for patterns Paid to Hunt for old metal |

£20

0s 0d £7 0s 0d £7 0s 0d £2 12s 6d £1 1s 6d £1 0s 0d £4 12s 3d 15s 0d 10s 0d £2 3s 0d 2s 0d 2s 4d 3s 0d 3s 6d £1 8s 10d 10s 3d 6s 2d £20 0s 0d |

April 20th, 1st Days Casting 1883

Castings Supplied Hanley Colliery Co.

| April

21st 15 Cage

Guides

4cwt 2qtr 13lbs May 15th 3 Gig Pulleys with Brake ring pins & Bored and fitted @ 17/6 each May 15th 6 Hammer heads @ 1/- each May 28th 1 Bending Block 7.0.0 @ 6/6 May 28th Pattern to Do May 28th 1 Mortar pan bottom 1 ton 3cwt -qtr -lbs May 28th Pattern to Do May 28th Drilling 88 holes 3/4 & holes for cages |

£4

12s 4d £2 12s 6d 6s 0 £2 5s 6d 7s 6d £6 18s 0d 5s 0 12s 0 |

Lingard Hulme Colliery

| April

29th For work at colliery R. Goodwin 1 1/4 days For work at colliery J. Goodwin 1 1/4 days

|

£1 9s 4 1/2d £1 8s 1 1/2d |

The

casting is the tub of a ‘beater’ used for processing paper pulp as part of the

paper manufacturing process.

In the background, the large cylindrical item, is the beater rotor.

probably the castings are for the nearby Brittans Ivy House Paper Mill

![]() I started work at Goodwin's in July 1969 when I was 16, I had applied for a job

in the laboratory at Shelton Bar steel works in Etruria but a similar job was

advertised at Goodwin's and fortunately I took the one at Goodwin. When I

started there were two other people in the laboratory and melting was carried

out on one shift. Melting was carried out in an electric arc furnace (producing

steel) and in a coke fired cold blast cupola (producing cast iron). The sand

moulds were made either on a semi automatic moulding line, or the large moulds

were made on the floor by hand. The sand was bound together with clays and about

3-4% water.

I started work at Goodwin's in July 1969 when I was 16, I had applied for a job

in the laboratory at Shelton Bar steel works in Etruria but a similar job was

advertised at Goodwin's and fortunately I took the one at Goodwin. When I

started there were two other people in the laboratory and melting was carried

out on one shift. Melting was carried out in an electric arc furnace (producing

steel) and in a coke fired cold blast cupola (producing cast iron). The sand

moulds were made either on a semi automatic moulding line, or the large moulds

were made on the floor by hand. The sand was bound together with clays and about

3-4% water.

![]() I

worked in the laboratory carrying out analysis of the metal by hand using

chemicals. The carbon level of the steel was very important so we had to check

the carbon while the molten metal was in the furnace - this took about 15

minutes. The furnace men were able to gauge the level of carbon by bending a

cooled sample of the metal, there was trouble to pay if the laboratory result

did not agree with what they though it should be. When the steel was cast the

laboratory staff analysed it for 4 other elements, this took about 1.5 hours.

I

worked in the laboratory carrying out analysis of the metal by hand using

chemicals. The carbon level of the steel was very important so we had to check

the carbon while the molten metal was in the furnace - this took about 15

minutes. The furnace men were able to gauge the level of carbon by bending a

cooled sample of the metal, there was trouble to pay if the laboratory result

did not agree with what they though it should be. When the steel was cast the

laboratory staff analysed it for 4 other elements, this took about 1.5 hours.

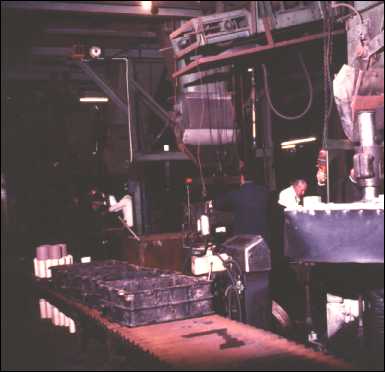

semi automatic moulding line

![]() Other duties included testing the sand on the moulding line for moisture level

and strength and sometime testing the mechanical strength of the castings so

they could be certified. Only about 1 cast in 50 required certification. The

floor moulding of the large castings was done by hand and was a skilled job. The

moulders told me that before the use of clays to bind the sand together they

used to use straw and horse manure!

Other duties included testing the sand on the moulding line for moisture level

and strength and sometime testing the mechanical strength of the castings so

they could be certified. Only about 1 cast in 50 required certification. The

floor moulding of the large castings was done by hand and was a skilled job. The

moulders told me that before the use of clays to bind the sand together they

used to use straw and horse manure!

![]() The firm had an apprentice scheme and I was enrolled in the trainee metallurgist

scheme. I attended the Northern Collage of Further Education on a day

release basis. We took chemistry at the Tunstall annex, chemistry and metallurgy

at the Wedgwood Institute in Burslem, engineering at the new collage buildings

in Moorland Road, Burslem and sometimes studied at the foundry collage at

Longton. Other students on the day release course were from Shelton Bar, Michelin

Tyre Co, Birketts and other local foundries. For the last two years of the City

and Guilds course we went to Wolverhampton and then Manchester University

because there were not enough students to continue the course at the local

collage.

The firm had an apprentice scheme and I was enrolled in the trainee metallurgist

scheme. I attended the Northern Collage of Further Education on a day

release basis. We took chemistry at the Tunstall annex, chemistry and metallurgy

at the Wedgwood Institute in Burslem, engineering at the new collage buildings

in Moorland Road, Burslem and sometimes studied at the foundry collage at

Longton. Other students on the day release course were from Shelton Bar, Michelin

Tyre Co, Birketts and other local foundries. For the last two years of the City

and Guilds course we went to Wolverhampton and then Manchester University

because there were not enough students to continue the course at the local

collage.

![]() The chemical analysis laboratory was right next to the furnaces and because of

the furnaces and Bunsen burners and muffles used was very hot. I remember

fainting one day because of the heat, eventually the laboratory was moved to a

larger building at the front of the factory.

The chemical analysis laboratory was right next to the furnaces and because of

the furnaces and Bunsen burners and muffles used was very hot. I remember

fainting one day because of the heat, eventually the laboratory was moved to a

larger building at the front of the factory.

Steve Birks operating the spectrograph (1973)

![]() Because the application for the castings the company was making was becoming

more important a direct reading spectrometer was installed in about 1973 to

carry out the chemical analysis. The spectrograph only needed one operator

(instead of three chemists) and could analyse 17 elements in 5 minutes (against

4 in 1.5 hours). At this time the order book was enough for there to be three

shifts and so there was no loss of jobs. The original spectrograph shown in the

photograph was connected to a teletypewriter and calibrated by hand. In about

1987 a newer spectrograph was installed which analysed 23 elements and is

computer controlled, the computer carries out the calibration automatically and

stores all the results obtained.

Because the application for the castings the company was making was becoming

more important a direct reading spectrometer was installed in about 1973 to

carry out the chemical analysis. The spectrograph only needed one operator

(instead of three chemists) and could analyse 17 elements in 5 minutes (against

4 in 1.5 hours). At this time the order book was enough for there to be three

shifts and so there was no loss of jobs. The original spectrograph shown in the

photograph was connected to a teletypewriter and calibrated by hand. In about

1987 a newer spectrograph was installed which analysed 23 elements and is

computer controlled, the computer carries out the calibration automatically and

stores all the results obtained.

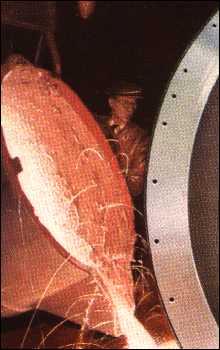

Tapping the 3 ton electric arc furnace (1980)

![]() Developments in melting furnaces:

Developments in melting furnaces:

![]() Later on I became one of the shift

metallurgists in charge of the melting furnaces, by this time the coke fired

cupola had been cut down. The company was starting to produce casting for more

critical applications, such as valves and high pressure pumps and cast iron was

not suitable for these applications. Also cold blast cupolas caused pollution

which was becoming more unacceptable and were inefficient, the cost to convert

to hot blast and to improve the arrester was not worth the investment. Now

(1999) the company has 4 electric furnaces with increased capacity (up to 10

tons) and also an AOD refining vessel (installed 1994) which produces very high

grade steel and nickel alloys used for power generation castings and other

critical applications.

Later on I became one of the shift

metallurgists in charge of the melting furnaces, by this time the coke fired

cupola had been cut down. The company was starting to produce casting for more

critical applications, such as valves and high pressure pumps and cast iron was

not suitable for these applications. Also cold blast cupolas caused pollution

which was becoming more unacceptable and were inefficient, the cost to convert

to hot blast and to improve the arrester was not worth the investment. Now

(1999) the company has 4 electric furnaces with increased capacity (up to 10

tons) and also an AOD refining vessel (installed 1994) which produces very high

grade steel and nickel alloys used for power generation castings and other

critical applications.

![]() The foundry developed and grew over the

years, more bays were added together with office space. Goodwin grew to become a

group of companies Goodwin Foundry in Hanley, Akron Standard in Newstead and

Hoben Davis in Newcastle-under-Lyme. In 1977 a new large three story building

was built at the Hanley site to accommodate the group offices. Following an

explosion in 1983 the foundry was extended and modernised.

The foundry developed and grew over the

years, more bays were added together with office space. Goodwin grew to become a

group of companies Goodwin Foundry in Hanley, Akron Standard in Newstead and

Hoben Davis in Newcastle-under-Lyme. In 1977 a new large three story building

was built at the Hanley site to accommodate the group offices. Following an

explosion in 1983 the foundry was extended and modernised.

![]() Developments in quality:

Developments in quality:

![]() When I joined Goodwin's typical castings were

20 - 1500 kg in weight, many were for local steel and pottery industries such as

Shelton Bar, Edwards & Jones, William Boulton. Few castings required special

certification. Over the years there has been a massive decline in the requirements

of local industry for castings and today over 75% of Goodwin's castings are

exported. Every single cast is tested and certified and every casting is given a

unique serial number so that it can be traced in the event of a problem.

When I joined Goodwin's typical castings were

20 - 1500 kg in weight, many were for local steel and pottery industries such as

Shelton Bar, Edwards & Jones, William Boulton. Few castings required special

certification. Over the years there has been a massive decline in the requirements

of local industry for castings and today over 75% of Goodwin's castings are

exported. Every single cast is tested and certified and every casting is given a

unique serial number so that it can be traced in the event of a problem.

![]() National and International developments in quality requirements lead to the

introduction of two standards for quality (BS5750 and ISO9000). In 1984

Goodwin's were the first steel foundry to be accredited to this standard.

National and International developments in quality requirements lead to the

introduction of two standards for quality (BS5750 and ISO9000). In 1984

Goodwin's were the first steel foundry to be accredited to this standard.

![]() Developments in health and safety:

Developments in health and safety:

![]() A section of a 1952 advert shows a foundry man

pouring iron with no protective equipment. But note the flat cap and the tie.

A section of a 1952 advert shows a foundry man

pouring iron with no protective equipment. But note the flat cap and the tie.

1952 picture of foundry man pouring iron

Compare this with the earlier picture tapping the electric arc furnace, special molten metal goggles and visors (to a British Standard) are worn together with helmets and spats (to stop metal splashing down the shoes). Although these were worn when around molten metal in other areas of the foundry only safety shoes were compulsory.

![]() Safety has developed in all foundries. Now at

Goodwin's regular safety meetings are held by the managers and also by workers

representatives. Helmets and eye protection are worn at all locations in the

factory and ear protection in noisy areas. The Health and Safety Executive make recommendations

for hearing tests and certain of the workers are tested every year for

"white finger vibration" (a problem which affected a lot of miners

using vibrating equipment). In 1998 the European "Working Hours

Directive" meant that a medical survey had to be offered for night shift

workers.

Safety has developed in all foundries. Now at

Goodwin's regular safety meetings are held by the managers and also by workers

representatives. Helmets and eye protection are worn at all locations in the

factory and ear protection in noisy areas. The Health and Safety Executive make recommendations

for hearing tests and certain of the workers are tested every year for

"white finger vibration" (a problem which affected a lot of miners

using vibrating equipment). In 1998 the European "Working Hours

Directive" meant that a medical survey had to be offered for night shift

workers.

![]() Environmental Developments:

Environmental Developments:

![]() In common with the pottery industry and many

others the foundry industry have had to reduce pollution and environmental

impact. The installation of extraction and cleaning plant for the melting

furnaces and other dusty operations helps Goodwin meet the requirements of the

"authorisation" to operate which Stoke-on-Trent council monitor. Sand

reclamation further reduces the impact on the environment.

In common with the pottery industry and many

others the foundry industry have had to reduce pollution and environmental

impact. The installation of extraction and cleaning plant for the melting

furnaces and other dusty operations helps Goodwin meet the requirements of the

"authorisation" to operate which Stoke-on-Trent council monitor. Sand

reclamation further reduces the impact on the environment.

![]() All new equipment such as compressors (1993) and heat treatment furnace (1999)

are designed to be energy efficient. In 1999 Goodwin's were accredited to the

new British Standard ISO14001 for Environmental Management, which means control

of energy, pollution, noise, use of resources, etc.

All new equipment such as compressors (1993) and heat treatment furnace (1999)

are designed to be energy efficient. In 1999 Goodwin's were accredited to the

new British Standard ISO14001 for Environmental Management, which means control

of energy, pollution, noise, use of resources, etc.

![]() Today:

Today:

![]() From the foundry in 1883 the Goodwin group

has grown to include a factory in Korea and office in Germany as well as a Radar

design and build company and in the last few year an Internet access and

authoring company. Gas from the North Sea, electricity from Southern Electric

together with castings for the Tsing Ma bridge in Hong Kong and Jianying bridge

in China in 1999 are a long cry from coke supplied by Granville and pulley

castings for Hanley Colliery in 1883.

From the foundry in 1883 the Goodwin group

has grown to include a factory in Korea and office in Germany as well as a Radar

design and build company and in the last few year an Internet access and

authoring company. Gas from the North Sea, electricity from Southern Electric

together with castings for the Tsing Ma bridge in Hong Kong and Jianying bridge

in China in 1999 are a long cry from coke supplied by Granville and pulley

castings for Hanley Colliery in 1883.

![]() Computers are used extensively in solidification simulation, stress analysis,

chemical analysis and control of the heat treatment furnaces. The payroll,

invoicing and accounting all need computers and you can find Goodwin's on the

Internet: www.goodwin.co.uk www.easat.co.uk

www.hoben.co.uk

Computers are used extensively in solidification simulation, stress analysis,

chemical analysis and control of the heat treatment furnaces. The payroll,

invoicing and accounting all need computers and you can find Goodwin's on the

Internet: www.goodwin.co.uk www.easat.co.uk

www.hoben.co.uk

click for details of the

Goodwin coat of arms

questions/comments? email: Steve Birks